All About Air Bearings and Related Information

B-type Air Bearings

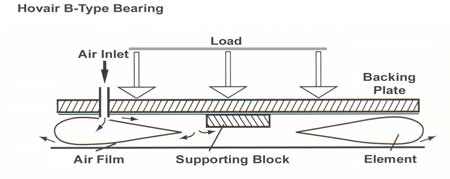

Hovair B-type air bearings are designed to lift loads vertically off

their base, then move laterally across floor surfaces to their

destination, then dropped into position. They function the same as A-type

bearings, but lift two to three times as much when pressurized.

Cross-section of a B-type air bearing.

The three stages of a B-type air bearing

operation.

Benefits of using b-type air bearings include:

-

B-type bearings consist of

a two-piece vulcanized body that is glued to an aluminum backing plate.

This rubber diaphragm can give a relatively high lift and operates at

higher air pressure.

-

B-type bearings are

preferred where low collapsed height, high lift, and capacity per

square inch are more important than wear, stability, and air

consumption efficiency.

-

Glued assemblies are

repairable when compared to other air bearings that are vulcanized or

riveted to the backing plate.

-

Superior lift height over

the A-type bearing. The B-type bearing is able to lift a load up to

three times the lift height of the A-type bearing, thus making it

possible to engage a load using a "lift & pick" movement similar to a

regular pallet truck.

-

B-type bearings stabilize

at 30 psi instead of 15 psi. This enables load capacities of double the

A-type bearing for the same size air bearing, but requires three times

the air consumption.

-

B-type bearings are also

available for air pallets, platform transporters, and air beams. These

products offer a broad selection when choosing the right bearing for

the job.

Be sure to contact us for

assistance in choosing the right air bearing for your particular job.

Return to All About Air Bearings

index

|